Electric forklifts address operating time requirements

Users of Kalmar electric forklifts can leverage the company’s considerable engineering expertise and insight into environmentally friendly powertrains to find a solution that supports the same operating cycle as a diesel-powered truck.

Queries from companies considering the transition from diesel to electric forklifts fall into two main categories. Firstly, whether the electric forklift will perform as well as a diesel-powered truck and secondly, the extent of the infrastructure requirement in terms of charging space and power supply.

Fortunately, Kalmar’s experience of selling electric forklifts since the 1980s means there is a considerable amount of information available to customers assessing the merits of these trucks. They also have access to a highly qualified sales organisation - backed up by technical support - that can guide them through the decision-making process.

Performance maintained

“From a performance perspective, there is little difference in load handling between electric and diesel-powered forklifts,” explains Andreas Cortelius, Portfolio Manager Forklift Trucks. “The differences can be found in the traction characteristics.”

The electric powertrain typically offers faster acceleration, full torque at low RPM, and greater energy efficiency. The latter is further supported by the absence of idling and features such as regenerative braking (which converts the kinetic energy generated by the action of braking into energy that can be returned to the battery).

“The diesel powertrain can offer higher travel speed and operate at steeper gradients, although at levels that in most cases are excessive for use in forklift applications,” adds Cortelius.

Field data supports the view that electric forklifts are just as productive as their diesel-powered counterparts.

Proven productivity

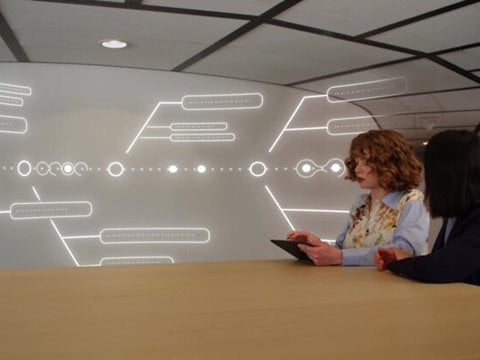

Field data supports the view that electric forklifts are just as productive as their diesel-powered counterparts. Almost all the latest generation of Kalmar forklift trucks send operational parameter data over the cloud to Kalmar Insight, a performance management tool for cargo handling operations that aggregates data from multiple sources.

“This information enables us and the customer to compare performance on electric and diesel forklifts, given that we are making an equal comparison in terms of size and application,” says Cortelius.

Customers can also be assured that the design of the forklift has not had to change radically to accommodate the replacement of a diesel engine with an electric powertrain. First generation electric forklifts - regardless of their size - use many of the same structural elements as the diesel version, thus utilising proven and reliable designs on lifting equipment and chassis design.

“The use of electric forklifts considerably improves the working environment for drivers and operators."

Enhanced environment

“The use of electric forklifts considerably improves the working environment for drivers and operators,” explains Cortelius. “Changing from diesel to electric significantly reduces noise and vibrations for the operator inside the cabin. However, the difference is even more pronounced for colleagues and others working around the machine due to reduced noise levels and the absence of exhaust fumes.”

These are also important factors in extending the operational capability and therefore the productivity of forklift trucks. Lower noise levels open up the possibility of running night time and weekend operations at sites close to residential areas, while zero emissions make it possible to use the machines in areas with emission restrictions, which have already been introduced in large cities around the world and will become more commonplace.

Customers can therefore be assured that switching from diesel to electric powered forklifts will not only cause minimal disruption to operations - it will also enable them to extend operations into locations and shift patterns that were previously inaccessible.

This article is part of a series exploring questions relating to the transition to electric vehicles. Below you can view the accompanying video interview:

Related articles

Further reading

Subscribe and receive updates in your email

Subscribe